Cognitive Factories: Merging Human Insight with AI-Driven Production

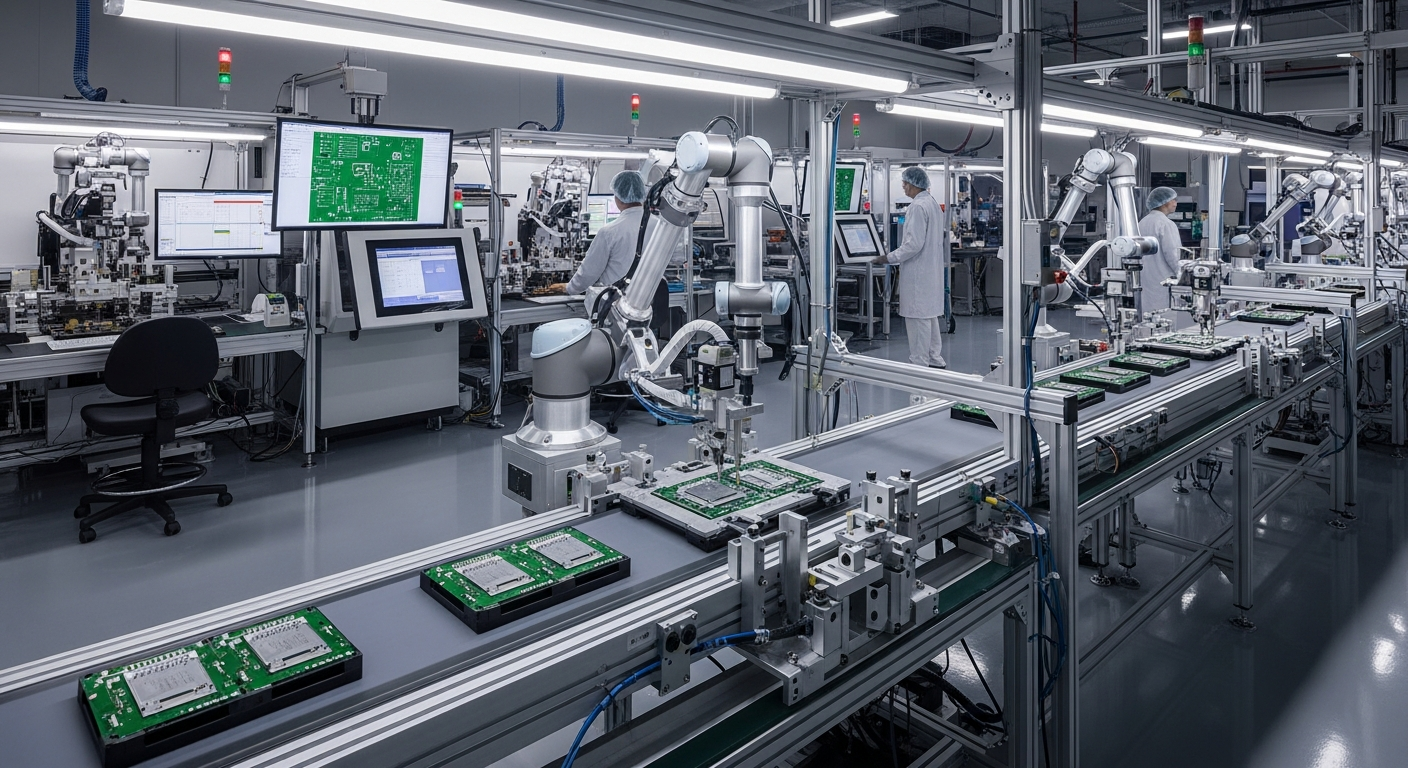

The fusion of human cognition and artificial intelligence in manufacturing is ushering in a new era of industrial innovation. Cognitive factories, a cutting-edge concept in smart manufacturing, are redefining how products are designed, produced, and delivered. This revolutionary approach combines human expertise with AI-driven systems to create highly adaptive, efficient, and intelligent production environments.

The Evolution of Intelligent Manufacturing

The concept of cognitive factories has its roots in the convergence of several technological advancements and industrial trends. Traditional manufacturing processes, while efficient, often lacked the flexibility and adaptability required to meet rapidly changing market demands. The advent of Industry 4.0 brought about significant improvements in automation and data exchange, but cognitive factories take this a step further by incorporating human-like reasoning capabilities into the production environment.

Early attempts at integrating artificial intelligence into manufacturing focused primarily on automating repetitive tasks and basic decision-making processes. However, these systems often fell short when faced with complex, unpredictable scenarios that required nuanced judgment. Cognitive factories address this limitation by combining the analytical power of AI with the creativity and intuition of human operators, creating a symbiotic relationship that enhances overall performance.

The Core Components of Cognitive Factories

At the heart of cognitive factories lies a sophisticated network of interconnected systems and technologies. These components work in harmony to create a dynamic, responsive production environment capable of adapting to changing conditions in real-time.

Machine learning algorithms form the foundation of cognitive factories, continuously analyzing vast amounts of data to identify patterns, predict outcomes, and optimize processes. These algorithms are complemented by advanced sensors and IoT devices that provide a constant stream of real-time information about every aspect of the production process.

Human operators play a crucial role in cognitive factories, acting as supervisors and decision-makers. Their expertise and intuition are augmented by AI-powered tools that provide data-driven insights and recommendations, enabling them to make more informed decisions and respond quickly to emerging challenges.

Enhancing Decision-Making and Problem-Solving

One of the key advantages of cognitive factories is their ability to enhance decision-making and problem-solving capabilities. By combining human expertise with AI-driven analytics, these systems can quickly identify and address issues that might otherwise go unnoticed or take significantly longer to resolve.

For example, in a cognitive factory setting, predictive maintenance algorithms can analyze equipment performance data to anticipate potential failures before they occur. This information is then presented to human operators, who can use their experience and judgment to determine the most appropriate course of action. The result is a more proactive approach to maintenance that minimizes downtime and extends the lifespan of critical equipment.

Adaptive Production and Customization

Cognitive factories excel in their ability to adapt to changing market demands and customer preferences. Traditional manufacturing processes often struggle with the need for flexibility, particularly when it comes to producing customized products at scale. Cognitive factories overcome this challenge by leveraging AI-driven systems to rapidly reconfigure production lines and optimize workflows in response to new requirements.

This adaptability extends to product design as well. By analyzing market trends, customer feedback, and production data, cognitive factories can suggest design modifications that improve product performance, reduce costs, or enhance manufacturability. Human designers can then refine these AI-generated suggestions, resulting in a more efficient and innovative product development process.

Quality Control and Defect Detection

Quality control is another area where cognitive factories shine. Advanced computer vision systems, coupled with machine learning algorithms, can detect even the smallest defects or inconsistencies in products as they move through the production line. These systems can learn from human quality control experts, gradually improving their ability to identify and classify defects over time.

Moreover, cognitive factories can analyze production data to identify the root causes of quality issues, enabling manufacturers to address problems at their source rather than simply detecting and rejecting defective products. This proactive approach to quality control leads to significant improvements in overall product quality and customer satisfaction.

Practical Insights for Implementing Cognitive Factories

• Start small: Begin by implementing cognitive technologies in specific areas of your production process before scaling up to a full cognitive factory.

• Invest in data infrastructure: Ensure you have robust systems in place for collecting, storing, and analyzing large volumes of production data.

• Focus on human-AI collaboration: Train your workforce to work effectively alongside AI systems, emphasizing the complementary nature of human and machine intelligence.

• Prioritize cybersecurity: As cognitive factories rely heavily on interconnected systems, robust cybersecurity measures are essential to protect against potential threats.

• Embrace continuous learning: Encourage a culture of continuous improvement and learning, both for your human workforce and your AI systems.

As we look to the future of manufacturing, cognitive factories stand out as a beacon of innovation and efficiency. By seamlessly integrating human expertise with artificial intelligence, these advanced production environments offer a glimpse into a world where manufacturing is not just smart, but truly intelligent. As businesses continue to explore and implement cognitive factory technologies, we can expect to see significant advancements in productivity, quality, and innovation across the industrial landscape.