Emerging Technologies in Electronics Manufacturing

The electronics manufacturing landscape is undergoing a significant transformation, driven by a continuous wave of technological advancements. From the intricate design of integrated circuits to the assembly of complex devices, new approaches and tools are reshaping how electronic products are conceived, produced, and delivered worldwide. This evolution is crucial for meeting the increasing demands for performance, efficiency, and miniaturization across various industries, pushing the boundaries of what is possible in modern production lines and supply chains.

The realm of electronics manufacturing is in a constant state of flux, characterized by rapid innovation that influences every stage of product development. This dynamic environment necessitates a keen understanding of the technologies emerging to enhance efficiency, precision, and scalability. As consumer and industrial demands intensify, manufacturers are leveraging sophisticated tools and methodologies to remain competitive and responsive to market shifts.

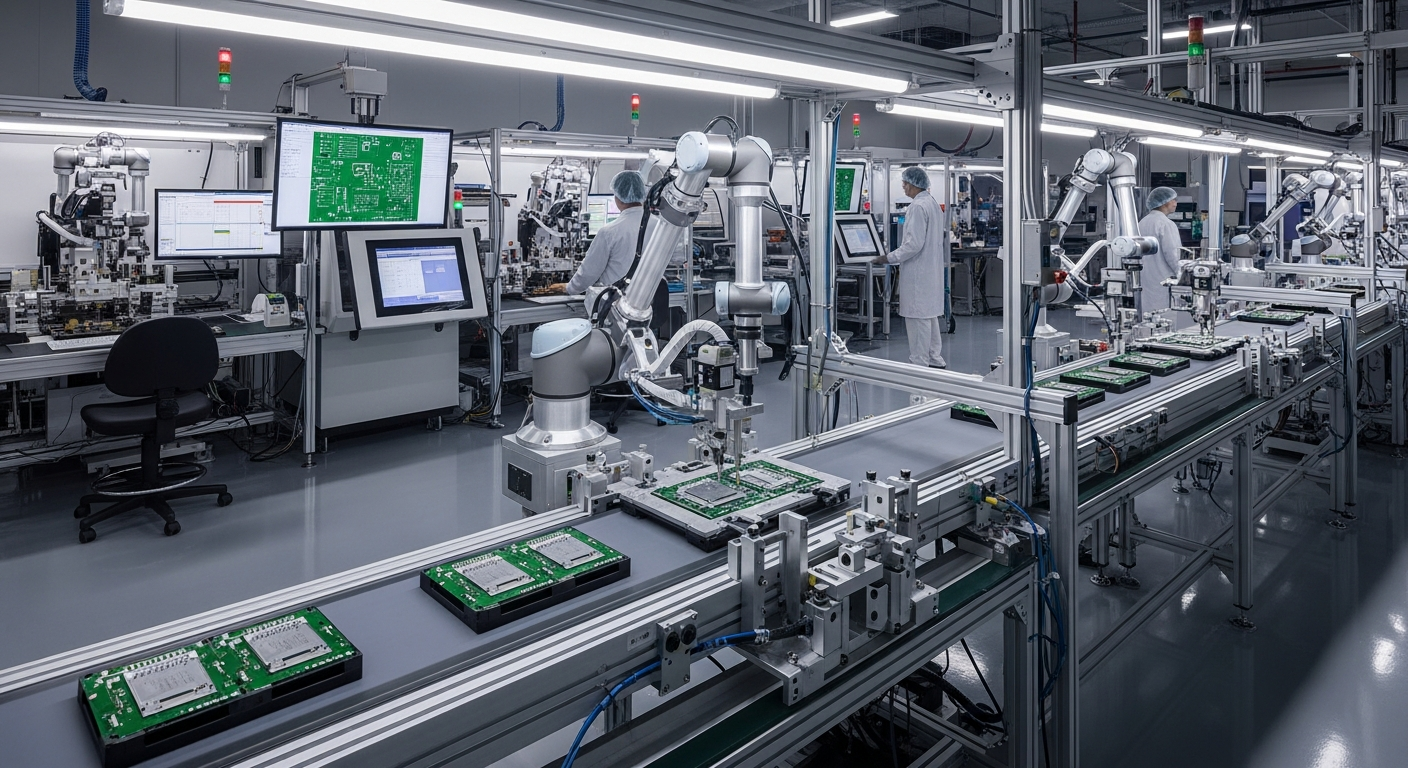

Advancements in Automation and Digital Systems

Automation plays a pivotal role in modern electronics manufacturing, extending beyond traditional robotics to encompass intelligent systems and advanced control mechanisms. Digital twins, for instance, create virtual replicas of physical production lines, allowing for real-time monitoring, simulation, and optimization without disrupting actual operations. This integration of digital and physical realms, often referred to as Industry 4.0, enables predictive maintenance, enhances quality control, and significantly reduces downtime. The use of artificial intelligence and machine learning algorithms further refines these processes, facilitating smarter decision-making and continuous improvement across manufacturing workflows. These sophisticated systems are vital for handling the complexity and precision required in producing today’s intricate electronic components and devices.

Innovations in Processors and Hardware Development

The core of any electronic gadget or system lies in its processors and the underlying hardware. Emerging technologies are pushing the boundaries of computing power, energy efficiency, and miniaturization. Advanced semiconductor manufacturing techniques, such as extreme ultraviolet (EUV) lithography, are enabling the creation of smaller, more powerful transistors, leading to faster and more efficient chips. Beyond silicon, research into novel materials like graphene and carbon nanotubes promises even greater performance enhancements. Furthermore, specialized hardware accelerators, designed for specific tasks like AI processing, are becoming commonplace, allowing for unprecedented computational capabilities in a wide array of devices. These innovations are fundamental to the progress of the entire electronics industry.

The Role of Advanced Connectivity in Modern Devices

Connectivity is an indispensable element of modern electronics, with technologies like 5G, Wi-Fi 6E, and upcoming 6G standards revolutionizing how devices communicate. In manufacturing, enhanced networks facilitate seamless data exchange between machines, sensors, and central control systems, enabling real-time monitoring and agile adjustments. For consumer electronics, improved connectivity translates to faster data transfer, lower latency, and more reliable connections, powering the growth of the Internet of Things (IoT) and smart ecosystems. The integration of advanced communication modules into a vast array of gadgets is transforming everything from home appliances to industrial machinery, fostering a more interconnected world and influencing how products are designed and tested for network performance.

Evolving Displays and Storage Technologies in Production

Displays and storage are two critical components that continually see significant innovation. In manufacturing, the production of flexible and rollable displays, utilizing technologies like OLED and MicroLED, requires highly specialized and precise fabrication techniques. These advancements are not just about visual quality but also about integrating displays into new form factors for various devices. Simultaneously, storage technologies are evolving with the advent of solid-state drives (SSDs) and novel memory solutions like MRAM and ReRAM, offering greater speed, durability, and capacity. Manufacturing these advanced storage mediums involves intricate processes to ensure data integrity and longevity. The integration of these components into products demands sophisticated assembly lines capable of handling delicate materials and complex architectures.

Data Integration and Modernization in Manufacturing Processes

The sheer volume of data generated throughout the electronics manufacturing process presents both a challenge and an opportunity. Emerging technologies focus on robust data integration frameworks that consolidate information from various stages, including design, production, testing, and supply chain logistics. This modernization allows for comprehensive analytics, predictive modeling, and enhanced traceability. By leveraging big data analytics, manufacturers can identify bottlenecks, optimize resource allocation, and improve product quality more effectively. The seamless flow and analysis of data are critical for maintaining competitive edge, driving efficiency, and ensuring that systems are responsive to dynamic market conditions and regulatory requirements.

Future Trajectories for Electronics Components

The future of electronics components is characterized by a drive towards greater integration, sustainability, and intelligent functionality. Research into self-healing materials and components that can adapt to environmental changes points towards a new era of resilient electronics. The development of advanced sensors that can detect a multitude of parameters with high accuracy is set to revolutionize monitoring and control systems across industries. Furthermore, the focus on sustainable manufacturing practices, including the use of recycled materials and energy-efficient production processes, is becoming increasingly prominent. These trends suggest a future where electronics are not only more powerful and interconnected but also more environmentally conscious and adaptable to diverse operational demands.

The ongoing evolution in electronics manufacturing is a testament to continuous human ingenuity and technological progress. From intelligent automation to advanced material science, the sector is consistently pushing boundaries, promising a future of increasingly sophisticated, efficient, and interconnected electronic devices and systems. These advancements are not only enhancing production capabilities but also shaping the very nature of the digital experiences that define our modern world.