Redefining Manufacturing with Biophilic Design

Integrating nature-inspired elements into industrial spaces for enhanced productivity and well-being In an era where manufacturing efficiency and employee wellness are paramount, a groundbreaking approach is gaining traction: biophilic design in industrial settings. This innovative concept merges the principles of biophilia—humanity's innate connection to nature—with the demands of modern manufacturing, creating environments that boost productivity, reduce stress, and foster sustainable practices.

Historically, factories and production facilities have been designed with a singular focus on functionality, often resulting in stark, artificial environments. However, as research continues to demonstrate the positive impact of nature on human cognition and well-being, forward-thinking manufacturers are reconsidering their approach to facility design.

The Business Case for Nature-Inspired Manufacturing Spaces

Implementing biophilic design in industrial settings isn’t merely an aesthetic choice; it’s a strategic business decision. Studies have shown that exposure to natural elements can increase productivity by up to 15%, reduce absenteeism, and improve overall job satisfaction. In manufacturing, where precision and focus are crucial, these benefits can translate to significant improvements in output quality and quantity.

Moreover, biophilic design aligns with the growing emphasis on corporate sustainability. By integrating natural systems into industrial processes, companies can reduce their environmental footprint while simultaneously creating more pleasant work environments. This dual benefit not only improves operational efficiency but also enhances brand image and employee retention.

Key Elements of Biophilic Design in Manufacturing

Implementing biophilic design in industrial spaces requires a thoughtful approach that balances nature-inspired elements with the practical requirements of manufacturing processes. Some key elements include:

-

Natural light: Maximizing daylight through strategic placement of windows, skylights, and light tubes.

-

Living walls: Incorporating vertical gardens to improve air quality and provide visual relief.

-

Biomorphic forms: Using organic shapes and patterns in architectural elements and equipment design.

-

Water features: Integrating flowing water elements to create a calming auditory environment.

-

Natural materials: Utilizing wood, stone, and other natural materials in construction and finishing.

Overcoming Challenges in Implementation

While the benefits of biophilic design are compelling, integrating these principles into industrial settings presents unique challenges. Safety regulations, cleanliness requirements, and the need for specialized equipment can limit the extent to which natural elements can be incorporated.

To address these challenges, manufacturers are turning to innovative solutions. For instance, antimicrobial plants can be used in cleanroom environments, while advanced air filtration systems allow for the integration of living walls without compromising air quality standards. Additionally, virtual reality and high-resolution displays can simulate natural environments in areas where physical implementation is impractical.

Case Studies: Success Stories in Biophilic Manufacturing

Several pioneering companies have already embraced biophilic design in their manufacturing facilities, providing valuable insights into its real-world applications:

-

A pharmaceutical company in Switzerland incorporated a central atrium with a living tree and surrounding gardens, resulting in a 15% increase in employee productivity and a significant reduction in errors.

-

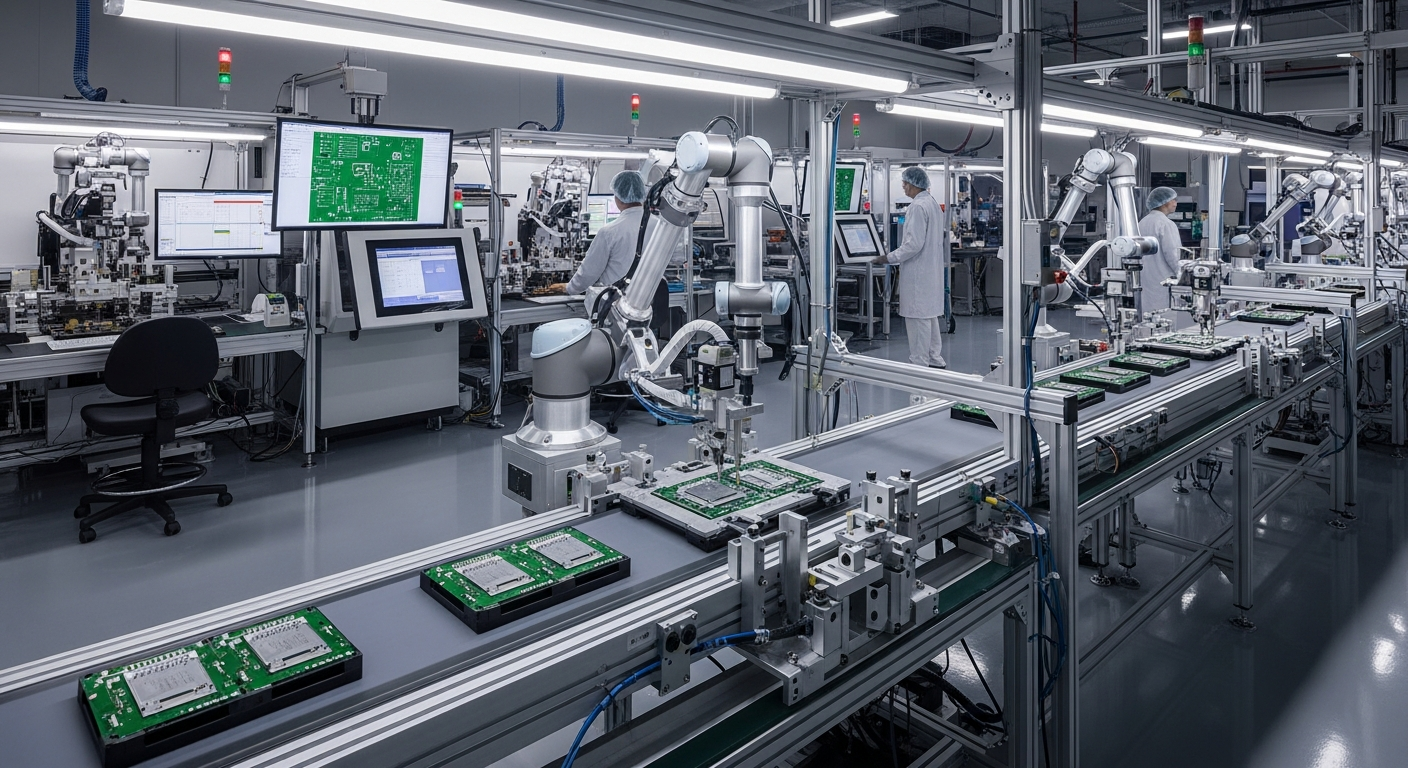

An electronics manufacturer in Japan redesigned its production floor to include natural light, indoor plants, and nature-inspired color schemes, leading to a 7% increase in output and a 23% decrease in reported stress levels among workers.

-

A food processing plant in the United States integrated a series of small indoor gardens throughout its facility, improving air quality and employee satisfaction while aligning with the company’s focus on natural ingredients.

Practical Strategies for Implementing Biophilic Design

• Conduct a biophilic audit of your current facility to identify opportunities for natural integration

• Prioritize access to natural light by reconfiguring workspaces and installing light-diffusing materials

• Introduce plant life through strategically placed potted plants, living walls, or outdoor green spaces

• Incorporate natural textures and materials in flooring, wall coverings, and furnishings

• Use nature-inspired colors and patterns in signage, equipment, and workspace design

• Implement water features or sound systems that mimic natural sounds to create a calming atmosphere

• Invest in air purification systems that allow for increased plant life without compromising cleanliness

• Consider outdoor work areas or break spaces to provide direct contact with nature

As the manufacturing industry continues to evolve, biophilic design represents a powerful tool for creating more humane, sustainable, and productive industrial environments. By thoughtfully integrating elements of nature into the factory floor, companies can cultivate spaces that not only enhance operational efficiency but also support the well-being of their workforce. As more manufacturers embrace this approach, we can expect to see a transformation in the way industrial spaces are conceived and constructed, ushering in a new era of harmony between nature, technology, and human productivity.