The Art of Engine Balancing: Precision in Motion

Revving engines, smooth acceleration, and the satisfying purr of a well-tuned motor – these are the hallmarks of automotive excellence. But behind this symphony of power lies a critical yet often overlooked aspect of engine design: balancing. From the earliest days of internal combustion to today's high-performance machines, engine balancing has played a pivotal role in automotive engineering. Let's dive into the intricate world of crankshafts, pistons, and counterweights to discover how the art of engine balancing shapes the driving experience we know and love.

The Science Behind the Balance

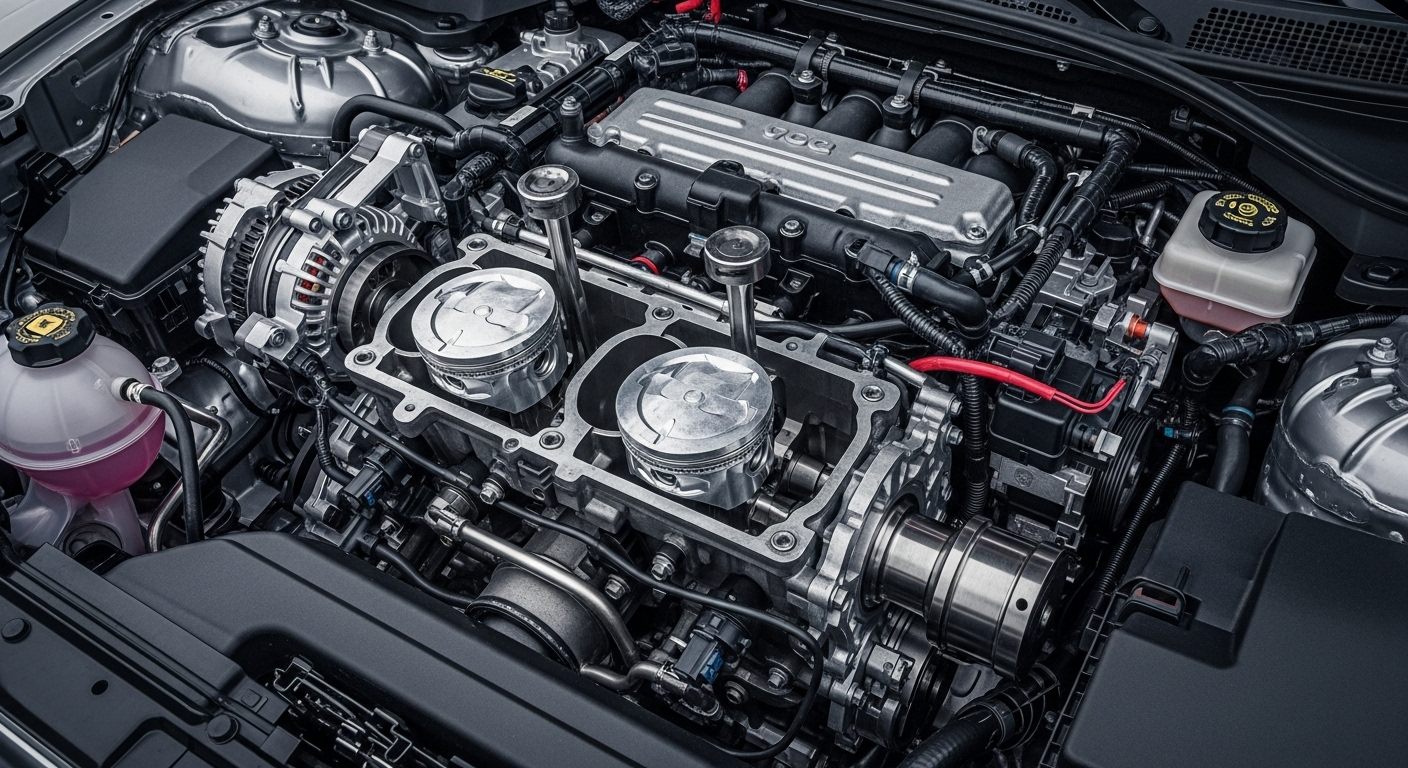

At its core, engine balancing involves two main types of forces: rotating and reciprocating. Rotating forces are generated by components like the crankshaft and flywheel, which spin continuously. Reciprocating forces come from parts like pistons and connecting rods, which move back and forth. The goal is to minimize these forces by ensuring that the weight is distributed as evenly as possible around the crankshaft’s axis of rotation.

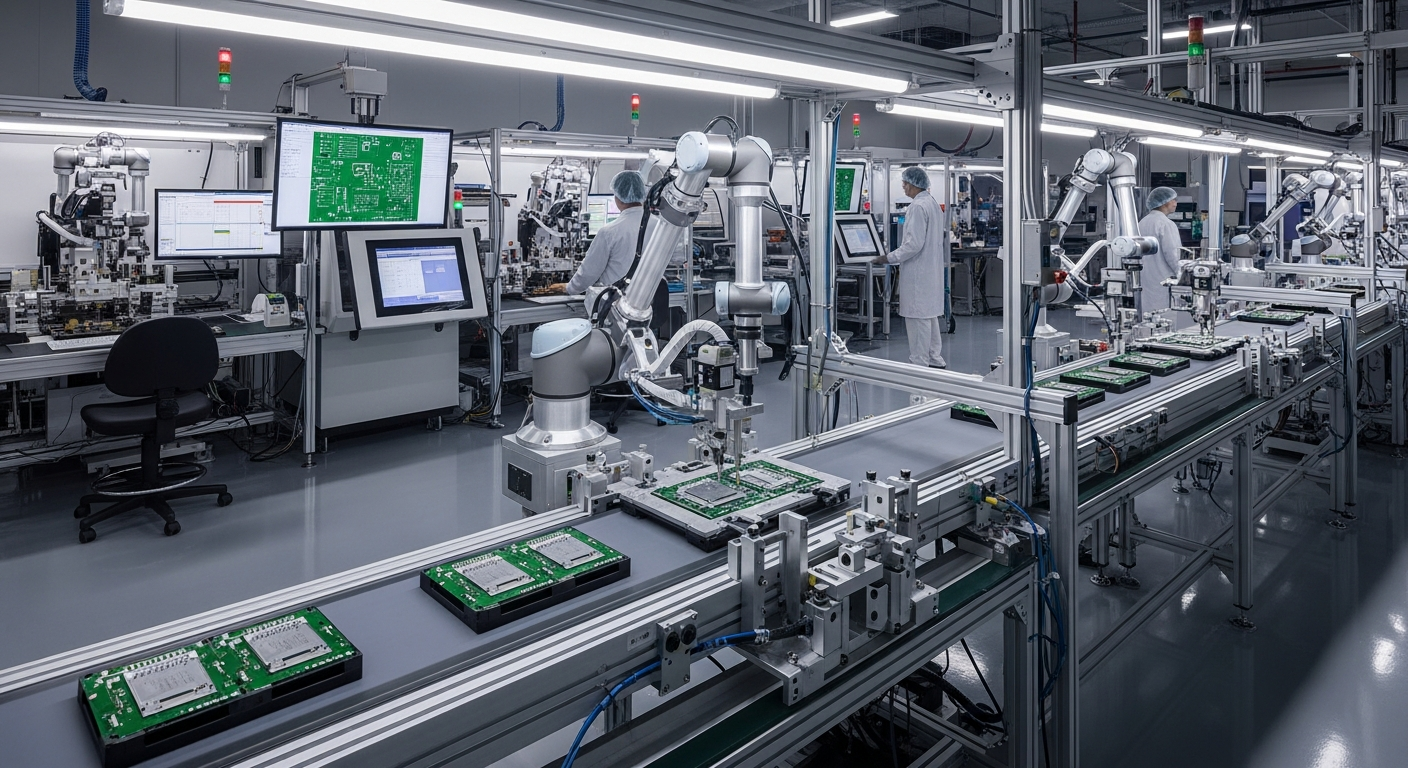

Precision Techniques in Modern Balancing

Today’s engine balancing techniques have evolved into a high-precision art form. Computer-aided design and manufacturing allow for incredibly tight tolerances, but the human touch remains crucial. Expert technicians use specialized equipment to measure and adjust the weight of individual components down to fractions of a gram. This process often involves adding or removing material from certain parts, such as drilling small holes in counterweights or adding metal to connecting rods.

The Impact on Performance and Longevity

A well-balanced engine offers numerous benefits that extend far beyond a smooth ride. Reduced vibration means less stress on engine mounts, bearings, and other components, leading to increased longevity. It also translates to improved fuel efficiency, as less energy is wasted overcoming internal forces. Perhaps most notably for enthusiasts, a properly balanced engine can rev higher and produce more power, as it experiences less internal resistance and can operate more efficiently at high RPMs.

Challenges in Multi-Cylinder Configurations

As engines have grown more complex, so too have the challenges of balancing them. Multi-cylinder configurations, particularly those with odd numbers of cylinders or unconventional layouts, present unique difficulties. Engineers must consider not only the primary balance (first-order forces) but also secondary and even tertiary imbalances. This has led to innovative solutions like balance shafts, which counter-rotate to offset inherent imbalances in certain engine designs.

The Future of Engine Balancing

Looking ahead, the art of engine balancing continues to evolve. Advanced materials and manufacturing techniques are pushing the boundaries of what’s possible, allowing for ever-tighter tolerances and more precise balance. Additionally, as alternative powertrains gain prominence, new challenges emerge. For instance, the integration of electric motors in hybrid systems introduces new variables to the balancing equation, requiring fresh approaches to ensure smooth, efficient operation.

Conclusion: The Unseen Artistry of Automotive Engineering

Engine balancing remains a testament to the intricate artistry hidden within every automobile. It’s a field where physics, engineering, and craftsmanship converge to create the smooth, powerful driving experiences we’ve come to expect. As automotive technology continues to advance, the principles of engine balancing will undoubtedly play a crucial role in shaping the future of transportation. The next time you feel the satisfying thrum of an engine, remember the countless hours of precision work that went into making that moment possible – a true celebration of automotive engineering at its finest.