Impact of Miniaturization on Gadget Design

Miniaturization has profoundly reshaped the landscape of modern electronics, transforming bulky devices into sleek, portable gadgets that seamlessly integrate into daily life. This ongoing trend, driven by relentless innovation in various technological domains, has not only altered the physical form factor of our devices but also expanded their capabilities and accessibility. Understanding the multifaceted influence of miniaturization is key to appreciating the evolution of contemporary digital tools and their pervasive presence across numerous industries and personal applications.

The relentless pursuit of smaller, more powerful electronic devices has been a defining characteristic of the tech industry for decades. This drive, commonly referred to as miniaturization, has fundamentally altered the design, functionality, and user experience of a vast array of gadgets. From smartphones to wearable technology and advanced industrial sensors, the ability to pack more processing power into increasingly compact forms has unlocked unprecedented possibilities, driving both consumer convenience and industrial efficiency across the globe.

How Semiconductors and Microchips Drive Miniaturization

At the core of miniaturization lies the extraordinary progress in semiconductor technology. The development of smaller, more efficient microchips has allowed engineers to integrate complex processing capabilities into tiny packages. These advanced semiconductors are the building blocks for virtually all modern electronics, enabling powerful computing within constrained spaces. The continuous shrinking of transistors, following principles like Moore’s Law, directly translates into more powerful and energy-efficient components, which are essential for creating the compact, high-performance gadgets we rely on daily. This foundational advancement underpins every subsequent step in device design.

Evolution of Hardware Components and Circuits

The impact of miniaturization extends beyond just microchips to all hardware components and circuits. Engineers have devised innovative ways to design and arrange internal components, optimizing space without compromising performance. Multi-layer circuit boards, surface-mount technology, and highly integrated system-on-a-chip (SoC) designs are prime examples of how hardware engineering has adapted. These advancements allow for the dense packing of components, reducing the overall footprint of devices while enhancing their processing capabilities. The challenge lies in managing heat dissipation and electromagnetic interference within these tightly packed circuits, pushing the boundaries of materials science and engineering.

Enhancing Portability and Connectivity in Gadgets

One of the most tangible benefits of miniaturization is the dramatic increase in the portability of gadgets. Devices that once required significant space and power are now small enough to fit in a pocket or be worn on the wrist. This enhanced portability is often paired with advanced connectivity options, such as Bluetooth, Wi-Fi, and cellular networks, allowing these compact devices to communicate seamlessly with each other and the internet. The combination of small size and robust connectivity has revolutionized personal communication, mobile computing, and the development of the Internet of Things (IoT), making smart environments and remote interaction more feasible and widespread.

The Role of Displays in Compact Device Design

As gadgets have shrunk, the role of displays has become even more critical. Innovations in display technology, such as flexible OLEDs and high-resolution LCDs, have been crucial in maintaining visual quality and user interaction within smaller form factors. Manufacturers strive to maximize screen-to-body ratios, often leading to edge-to-edge displays or even foldable screens, which offer larger viewing areas on devices that remain highly portable. The integration of touch sensitivity and advanced graphical processing capabilities within these compact displays further enhances the user experience, making interaction intuitive and engaging.

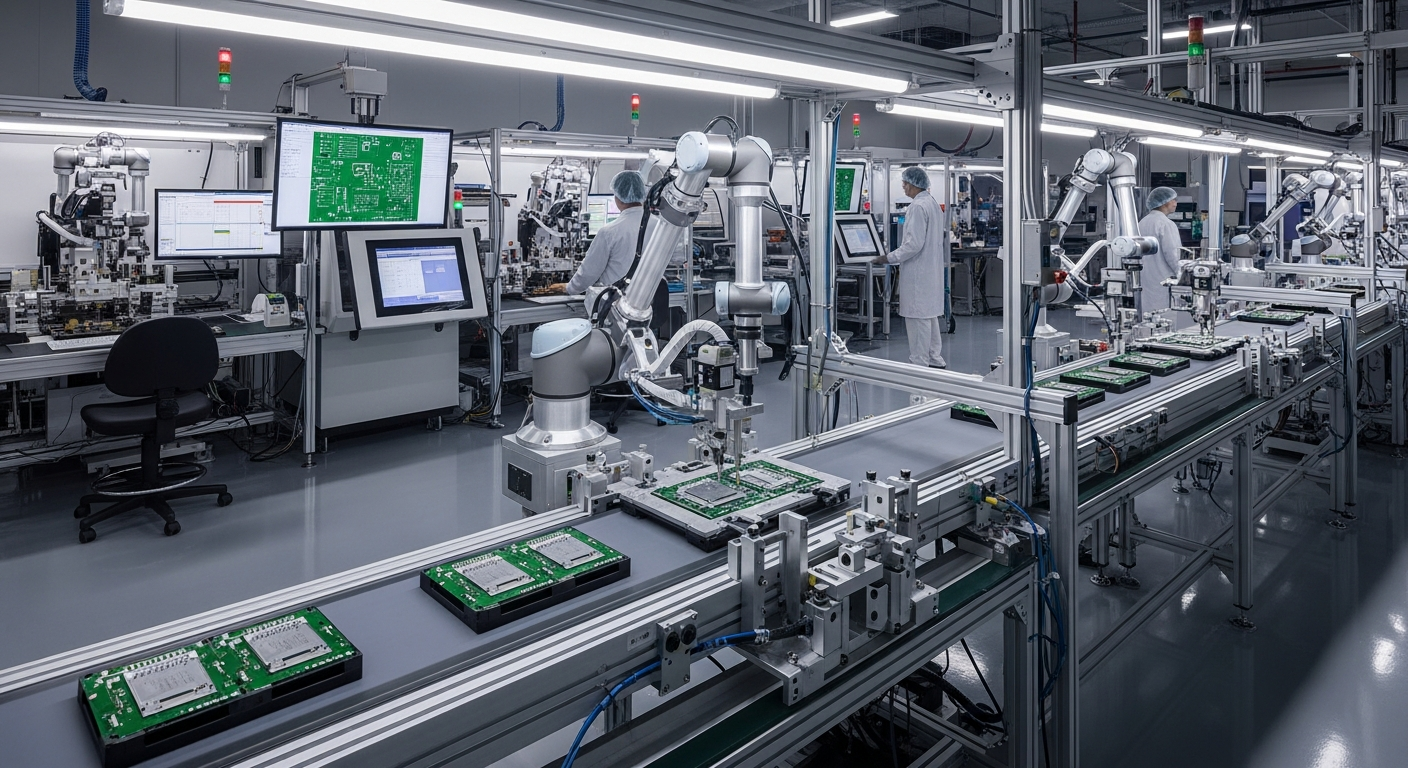

Engineering Materials and Innovation for Smaller Footprints

The drive for miniaturization also heavily relies on advancements in engineering materials and manufacturing innovation. Lighter, stronger, and more durable materials are essential for creating thin, resilient device casings that protect delicate internal components. Innovations in battery technology, which allow for greater energy density in smaller volumes, are equally vital for powering these compact gadgets for extended periods. Furthermore, advanced manufacturing techniques, including precision molding and automated assembly, are indispensable for producing these intricate devices at scale, ensuring consistent quality and performance for complex products.

Miniaturization’s Broader Impact on Productivity

Beyond individual gadgets, miniaturization has had a significant impact on overall productivity across various sectors. Smaller, more powerful tools enable field workers to perform complex tasks more efficiently. In healthcare, miniature diagnostic devices facilitate quicker and less invasive procedures. In industrial settings, compact sensors and control systems allow for more precise monitoring and automation of processes. This enhanced productivity stems from the ability to deploy sophisticated technology in environments where space or mobility was previously a limiting factor, fostering innovation and creating new opportunities for efficiency gains worldwide.

Miniaturization continues to be a driving force in the evolution of electronics, shaping how we interact with technology and the world around us. By making devices smaller, more powerful, and more interconnected, it has not only enhanced convenience for individual users but also spurred significant advancements across industries. The ongoing push for even greater integration and efficiency promises to deliver further transformative innovations in the years to come, continually redefining the capabilities and reach of modern gadgets.