Securing Industrial Control Systems from Cyber Threats

Industrial Control Systems (ICS) form the backbone of modern infrastructure, spanning manufacturing, energy, water treatment, and transportation. These systems are crucial for automated operations and efficient production processes. However, their increasing connectivity to broader networks exposes them to sophisticated cyber threats, necessitating robust security strategies to maintain operational integrity and prevent potentially catastrophic disruptions.

Understanding Industrial Control Systems and Their Vulnerabilities

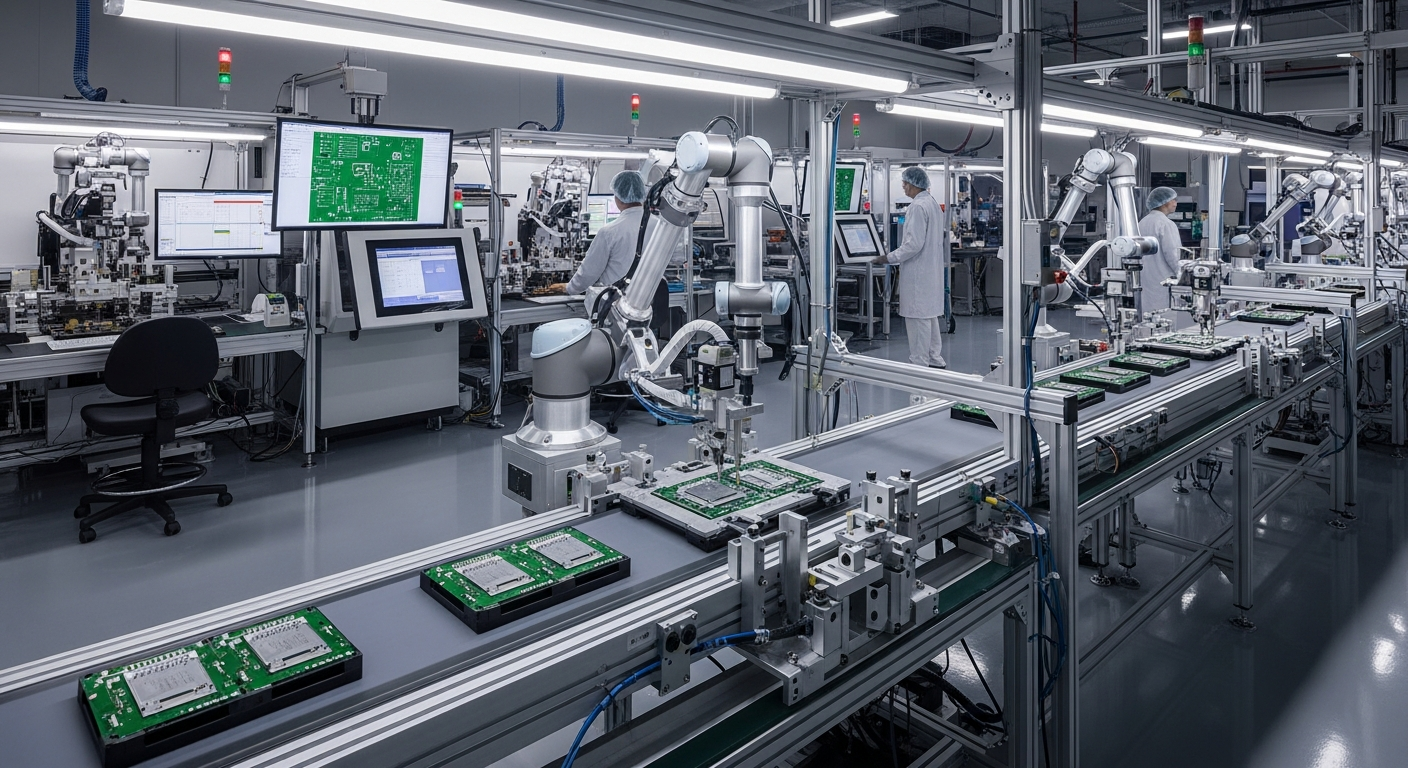

Industrial Control Systems (ICS) encompass a wide array of control systems and associated instrumentation, including Supervisory Control and Data Acquisition (SCADA) systems, Distributed Control Systems (DCS), and other smaller control system configurations such as Programmable Logic Controllers (PLCs). These systems are fundamental to the efficient automation and production across various industry sectors. They manage everything from the precise movements of robotics on an assembly line in manufacturing facilities to the intricate processes governing power grids and chemical plants.

While designed for reliability and specific operational tasks, many legacy ICS were developed before widespread internet connectivity, meaning security was not a primary design consideration. This inherent vulnerability, coupled with the increasing integration of digital technology and IT networks, creates significant entry points for cyber attackers. Threats can range from intellectual property theft and data manipulation to direct operational disruption, potentially leading to physical damage, environmental incidents, or threats to public safety.

The Evolving Landscape of Cyber Threats in Manufacturing

The manufacturing sector, in particular, has become a prime target for cyber threats due to its reliance on interconnected systems for efficiency and supply chain logistics. Attackers are increasingly sophisticated, employing methods such as ransomware, phishing, and advanced persistent threats (APTs) specifically tailored to exploit ICS vulnerabilities. The motivation behind these attacks varies, from financial gain and industrial espionage to nation-state-sponsored sabotage.

The convergence of IT (Information Technology) and OT (Operational Technology) networks, while offering benefits in terms of data analytics and remote operations management, also expands the attack surface. This integration means that a cyber incident originating in the IT network, such as an email-borne malware infection, could potentially propagate to the OT network, impacting critical industrial processes and halting production. Understanding these evolving threats is the first step in building effective defenses.

Implementing Robust Security Measures for Operational Resilience

Building resilience into ICS environments requires a multi-layered approach to security. This begins with a thorough risk assessment to identify critical assets and potential vulnerabilities. Network segmentation is a foundational security measure, isolating OT networks from IT networks and further segmenting critical control systems internally. This limits the lateral movement of attackers within the network, containing potential breaches.

Implementing strong access controls, including multi-factor authentication, is crucial for protecting sensitive ICS components. Regular patching and vulnerability management, although challenging in OT environments due to uptime requirements, are also essential. Furthermore, deploying specialized industrial firewalls, intrusion detection systems (IDS), and security information and event management (SIEM) solutions tailored for OT can provide real-time monitoring and threat detection capabilities, enhancing overall operations security.

The Role of Workforce Training and Digital Innovation in ICS Security

Even the most advanced technology solutions are ineffective without a well-trained workforce. Human factors often contribute to security incidents, whether through social engineering attacks or accidental misconfigurations. Comprehensive training programs are vital to educate employees on best security practices, threat recognition, and incident response protocols. This empowers personnel to be the first line of defense, fostering a culture of security awareness across the organization.

Digital innovation also plays a significant role in enhancing ICS security. Technologies like artificial intelligence (AI) and machine learning (ML) can be leveraged for predictive analytics to detect anomalous behavior within ICS networks, identifying potential threats before they escalate. Secure remote access solutions and robust data backup and recovery plans are also critical components that support continuous operations and minimize downtime in the event of a cyber incident.

Leveraging Analytics and Automation for Enhanced Protection

Advanced analytics provide deep insights into the operational state and security posture of ICS. By collecting and analyzing data from various sensors, control devices, and network traffic, organizations can establish baselines of normal behavior. Any deviation from these baselines can trigger alerts, indicating potential anomalies or cyber attacks. This proactive monitoring capability is essential for early threat detection and rapid response.

Automation in security, such as automated incident response playbooks, can significantly reduce the time it takes to detect, contain, and remediate cyber threats. While full automation of response in OT environments requires careful consideration due to the potential for operational disruption, automated alerts and initial containment actions can greatly improve efficiency in managing security incidents. This integration of analytics and automation creates a more dynamic and responsive security framework for protecting critical industrial processes.

Securing Industrial Control Systems from cyber threats is a complex and ongoing challenge that requires a holistic approach. By understanding the unique vulnerabilities of ICS, staying informed about evolving threat landscapes, implementing robust technical and procedural security measures, investing in workforce training, and leveraging digital innovation and analytics, organizations can significantly enhance their resilience against cyber attacks. Continuous vigilance and adaptation are key to maintaining the integrity and safety of critical industrial operations in an increasingly interconnected world.