Supply Chain Resilience: Navigating Global Economic Shifts

Global economic shifts are reshaping how organizations approach supply chain management. From geopolitical tensions to technological disruptions, companies face unprecedented challenges requiring adaptive strategies. Understanding resilience principles helps enterprises maintain operational continuity while responding to market volatility, regulatory changes, and evolving consumer demands across international markets.

Modern supply chains operate within increasingly complex environments where disruption has become the norm rather than the exception. Organizations must develop robust frameworks that balance efficiency with flexibility, enabling them to withstand shocks while maintaining competitive positioning. This requires comprehensive understanding of risk factors, strategic planning, and investment in capabilities that support rapid adaptation.

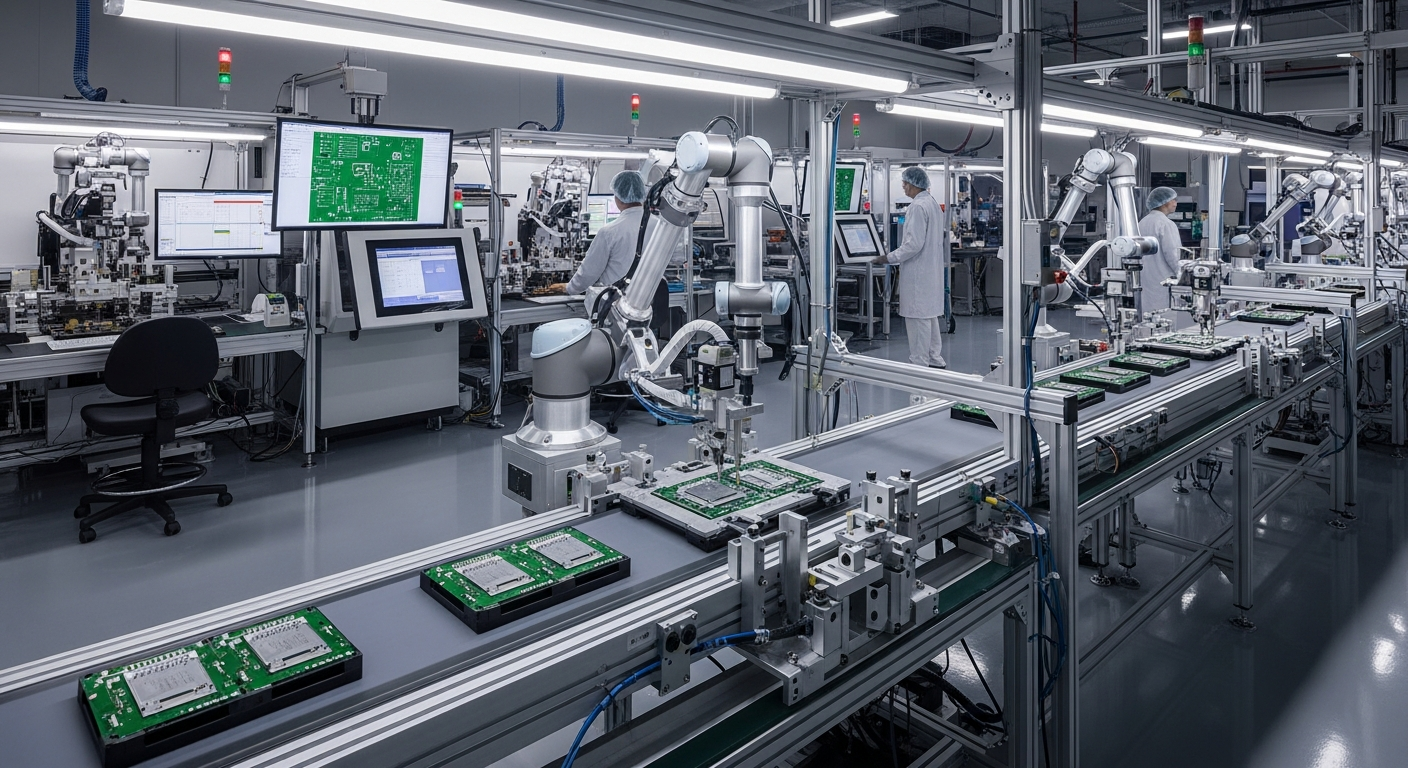

How Does Automation Enhance Manufacturing Resilience?

Automation technologies transform manufacturing operations by reducing dependency on manual processes vulnerable to labor shortages and human error. Robotics, artificial intelligence, and machine learning systems enable production facilities to maintain output consistency during workforce disruptions. Automated quality control systems detect defects earlier, minimizing waste and rework costs. Smart factories equipped with interconnected sensors provide real-time visibility into equipment performance, allowing predictive maintenance that prevents costly downtime. Companies implementing automation report improved production efficiency ranging from 20 to 40 percent, alongside enhanced worker safety through reduced exposure to hazardous tasks. However, automation requires significant capital investment and workforce retraining programs to ensure successful implementation.

What Role Does Logistics Play in Global Strategy?

Logistics networks form the backbone of international commerce, connecting raw material sources with manufacturing facilities and end consumers. Strategic logistics planning involves diversifying transportation modes, carrier relationships, and route options to mitigate disruption risks. Multi-modal transportation strategies combining ocean freight, air cargo, rail, and trucking provide flexibility when individual channels face capacity constraints or delays. Nearshoring and regionalization trends reflect companies repositioning inventory closer to key markets, reducing transit times and exposure to long-distance shipping vulnerabilities. Advanced logistics management systems integrate real-time tracking, demand forecasting, and inventory optimization algorithms that balance service levels against carrying costs. Organizations investing in logistics resilience typically maintain buffer inventory at strategic locations, establish backup supplier relationships, and conduct regular scenario planning exercises.

How Can Enterprise Technology Support Operations Management?

Enterprise technology platforms integrate disparate business functions into unified systems that enhance visibility and coordination across supply chain operations. Cloud-based solutions enable remote access to critical data, supporting distributed decision-making during crisis situations. Digital twins create virtual replicas of physical supply chains, allowing managers to simulate disruption scenarios and test response strategies without operational risk. Blockchain technology provides transparent, tamper-proof records of transactions and product movements, improving traceability and reducing counterfeiting risks. Application programming interfaces facilitate seamless data exchange between internal systems and external partner platforms, accelerating information flow. Companies leveraging enterprise technology report 25 to 35 percent improvements in order fulfillment accuracy and 15 to 20 percent reductions in inventory carrying costs through enhanced demand visibility.

What Sustainability Practices Strengthen Supply Chain Development?

Sustainability initiatives increasingly influence supply chain design as organizations respond to regulatory requirements, investor expectations, and consumer preferences. Circular economy principles encourage material reuse, remanufacturing, and recycling programs that reduce resource dependency and waste generation. Renewable energy adoption in production facilities and distribution centers lowers carbon footprints while providing energy cost stability. Sustainable sourcing practices evaluate suppliers based on environmental performance, labor standards, and ethical governance, reducing reputational risks. Transportation optimization reduces fuel consumption through route planning, load consolidation, and fleet electrification programs. Companies embedding sustainability into supply chain strategy often discover operational efficiencies that improve both environmental performance and financial results. Green supply chain initiatives typically require three to five years to generate measurable returns but create competitive advantages in markets prioritizing environmental responsibility.

How Do Analytics and Innovation Drive Efficiency Improvements?

Advanced analytics transform raw supply chain data into actionable insights that guide strategic and tactical decisions. Predictive analytics models forecast demand patterns, identify emerging risks, and optimize inventory positioning across networks. Prescriptive analytics recommend specific actions to address detected issues, such as alternative sourcing options when suppliers face capacity constraints. Machine learning algorithms continuously improve forecast accuracy by identifying complex patterns human analysts might overlook. Innovation in sensor technology, Internet of Things devices, and edge computing enables real-time monitoring of product conditions during transit, particularly critical for temperature-sensitive or fragile goods. Companies implementing analytics-driven approaches report 10 to 15 percent improvements in forecast accuracy and 20 to 30 percent reductions in expedited shipping costs through better planning.

What Workforce and Trade Considerations Impact Global Operations?

Workforce capabilities determine organizational capacity to implement and sustain supply chain improvements. Skills gaps in areas like data analytics, digital technology management, and sustainability expertise constrain innovation adoption. Successful companies invest in continuous learning programs, cross-functional training, and partnerships with educational institutions to develop talent pipelines. Trade policy shifts, tariff changes, and regulatory divergence create compliance complexity requiring specialized expertise. Free trade agreements, customs procedures, and documentation requirements vary significantly across regions, necessitating local knowledge and adaptable processes. Labor availability fluctuations, wage inflation, and changing workforce expectations influence location decisions for production and distribution facilities. Organizations building resilient supply chains prioritize workforce development alongside technology investments, recognizing that human capital remains essential for navigating uncertainty and driving continuous improvement.

Conclusion

Building supply chain resilience requires holistic approaches integrating technology, process optimization, strategic partnerships, and workforce development. Organizations succeeding in volatile global markets balance efficiency with flexibility, invest in visibility and analytics capabilities, and maintain diverse supplier and logistics networks. While challenges persist, companies prioritizing resilience position themselves to capitalize on opportunities emerging from economic shifts while protecting operations against disruption. Continuous adaptation, informed by data-driven insights and supported by skilled teams, enables enterprises to navigate uncertainty and maintain competitive advantage in evolving global markets.